MACHINING

Machining

We handle a wide variety of resins, stainless steel, aluminum, and glass epoxy sheets.

-

- Even if you do not have specific product images, we provide services from the design stage - from jig design to realization planning.

-

- We polish aluminum and resin materials of 330 × 330 (mm) in spatial dimensions and from 1 ton through 30 tons in weight.

-

- We have the capacity to produce optimal jigs and tools in-house for individual production processes, thus distinguishing ourselves from competitors.

-

- Owning three-dimensional CAD and CAM turntables and necessary equipment, we handle a complete flow of production, from complicated three-dimensional processing to surface treatment.

High quality

- Our strict quality control ensures high-quality component processing.

- We are perfectly versed in the properties of raw materials and realize unparalleled quality and precision.

- Our comprehensive quality control actions include the collection of data on past failures, and data feedback on repeatedly ordered products and products similar to those that have failed in the past.

Short lead time

- A network system centrally controls production progress to respond to short-lead-time needs.

- Having placed monitors in each of our factories, we check production progress via personal computers and mobile phones to realize efficient production.

- A specialized production system enables us to ship products according to customers' needs.

- Materials we are experienced in machining

- We handle a great variety of resins, stainless steel, aluminum, and glass epoxy sheets.

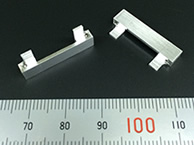

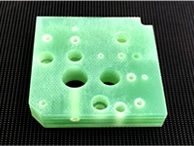

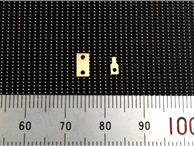

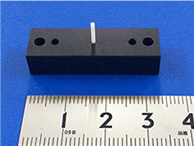

Examples of processing

Aerial components (aluminum)

Semiconductor components (glass epoxy)

Contact-point terminals (copper)

Medical component jigs (plastic)

iPhone cases (aluminum)

Absorption bases (metal)

Semiconductor components (stainless steel)

Fixtures (aluminum)