SPECIAL PROCESSING

Special processing

-

DRILLING Drilling

- We can process holes from 0.1 mm to 6.2 mm in diameter at low cost. Processing of unpenetrated holes is also possible.

- The processing precision can be in a range of ±30 μm to ±50 μm for both hole positions and outline dimensions.

- We are also experienced in additional machining on three-dimensional molded objects on a mass-production basis.

-

ROUTING Routing

- High-precision mass microfabrication and cutting are available.

- Using the best machine for each material, we process plastics, metallic, carbonic, and various other materials two- and three-dimensionally.

- We are also able to perform highly precise special processing, such as mirror machining and counterboring.

-

- Increased productivity thanks to multiaxial simultaneous processing

- No initial cost required, such as mold cost

-

- Supply-chain management available

Global services by our factories in China

- Materials we are experienced in routing

-

We are able to process a great variety of materials:

Acryl, polycarbonate, PET, vinyl chloride, Bakelite®, Unilate®, carbon (CFRP), glass epoxy sheets, PPS, aluminum, copper, electronic components, laminated plates, engineering plastics, ceramics

Examples of processing

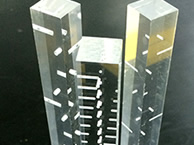

Non-through holes (acrylic)

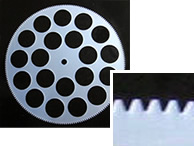

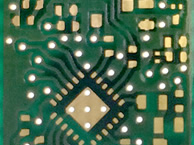

Carrier boards (glass epoxy)

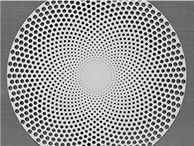

Decorative holes (ABS)

Design components (polycarbonate)

Jig holes

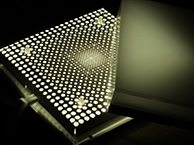

Electronic components (layered PCB)

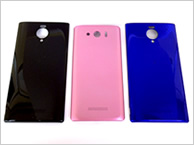

Holes for loudspeakers and tablets (molded products)

Holes for loudspeakers and cameras (molded products)